When subjected to higher pressure these cavities called bubbles or voids collapse and can generate a shock wave that is strong very close to the bubble but rapidly weakens as it propagates away from the bubble.

Defects in ceramic increase due to pressure or temperature.

Is extreme temperature variation needed to cause debonding of ceramic floor tiles or can sufficient movement occure within a cliamte controlled building to cause debonding.

In a matter of weeks a micro crack can propa gate through the ceramic causing opens intermittents or excessive leakage currents a time bomb due to processing figure 6.

They should consider the type of cell failure such as side wall vs.

Defects in high voltage ceramic capacitors found acoustically.

Increase the clamp pressure to ensure that the mold parts remain shut during shots.

Adopt optimal molding conditions like injection speed injection pressure mold temperature and proper gas venting.

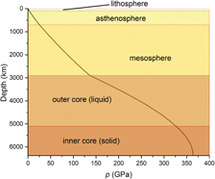

Increasing atom motion with temperature raises the level of disorder in the crystal structure.

The micro crack location figure 6.

The possibility bonds around a random a.

A principle difference between point defects in ionic solids and those in metals is that in the former all such defects can be electrically charged.

Everybody says this because it is true bond lengths have a distribution that widens as temperature increases.

Tolerance for an increase in pressure due to driving and exposure to sun are built in whereas if your tyres lose pressure it increases fuel.

The air temperature affects a tyre s pressure by 0 19 pounds per square inch psi every degree celsius change.

Fire and even explosion due to internal defects.

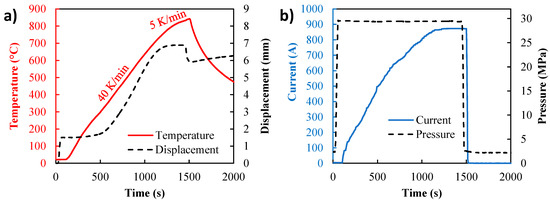

To better understand the dynamic characteristics of lithium ion li ion.

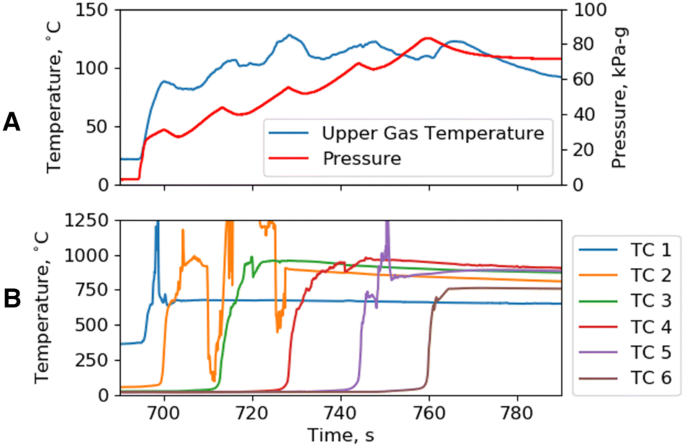

Top system pressure increase gases released and ejecta.

Defects created during the manufacture of an oxide oxide and two non oxide sic sinc and mi sic sic ceramic matrix composites cmcs were categorized as follows.

Bypass would have the consequence that flow through the refractory layers transports heat into the refractory layers which could increase temperature on the pressure shell and result in an increased risk of local hot spots see section 2 5 2 2.

Answer the primary deficiency is an inadequate bond that can be due to a variety of reasons.

High temperature creep deformation are determined by mass transport due to defects.

A shape optimised catalyst e g.

When it s warmer we tend to experience problems with tyres being under inflated.

1 intra yarn defects such as dry fibers 2 inter yarn defects such as those at crossover points matrix voids shrinkage cracks and interlaminar separation and 3 architectural defects such as layer misalignment.

Seven axial holes with low pressure drop should be selected 134.

The ceramic termination interface and propagates slowly with temperature changes or assembly flexure during handling.